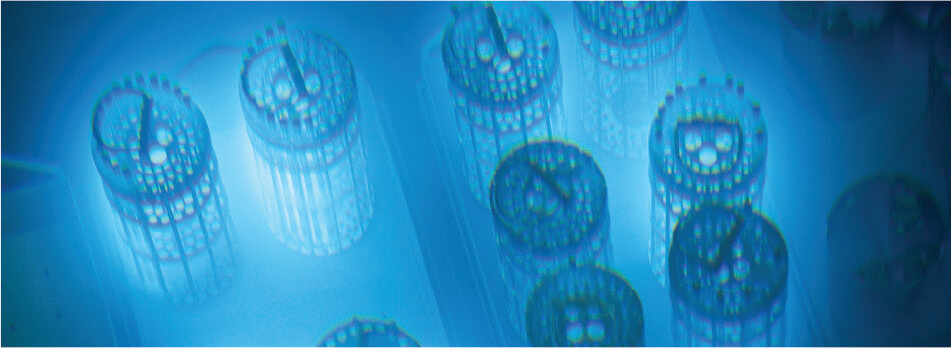

Os irradiadores gama são alimentados por cobalto-60,

um isótopo que produz irradiação gama. A irradiação gama é uma forma de energia eletromagnética caracterizada por penetração profunda, exterminando efetivamente os microrganismos do produto e da embalagem, com muito pouco efeito de temperatura e sem deixar resíduos.

Entre em contato conosco para iniciar seu projeto

Entre em contato conosco

A irradiação gama é altamente eficaz no tratamento de uma ampla gama de dispositivos médicos, produtos farmacêuticos, alimentícios e comerciais, além de melhorar as propriedades de muitos tipos diferentes de materiais.

A esterilização por irradiação gama com Cobalto-60 é respaldada por décadas de ciência, tecnologia e padrões bem desenvolvidos, garantindo segurança, confiabilidade e eficácia.

Para ultraprecisão e repetibilidade, pergunte-nos sobre:

Com uma grande rede global e décadas de experiência no setor, a irradiação gama continua sendo uma tecnologia de esterilização ideal para dispositivos médicos descartáveis, produtos farmacêuticos, alimentos e outros produtos.

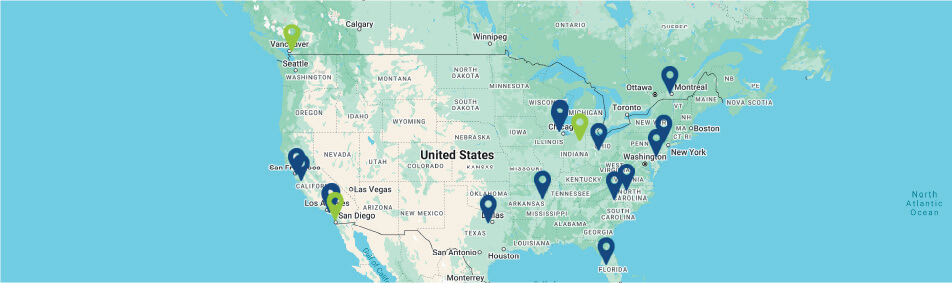

A rede de quase 300 instalações de irradiação gama estabelecidas ao longo da longa história do setor fornece capacidade robusta para cadeias de suprimentos que dependem da etapa crítica de esterilização para ajudar a garantir a segurança dos produtos para pacientes e profissionais de saúde.

Desde 2015, mais de 20 novas instalações de irradiação foram construídas em 10 países. Nossa empresa irmã Nordion, fornecedora líder de Cobalto-60 há mais de 70 anos, está envolvida em projetos contínuos para construir ainda mais instalações conforme a capacidade de irradiação gama continua crescendo junto com a demanda.

Nordion, nossa empresa irmã, está fazendo investimentos contínuos significativos para manter fontes nacionais de Cobalto-60 enquanto expande e diversifica sua rede.

Na Sterigenics, estamos empenhados em atender à crescente necessidade de soluções de esterilização e em fazer parcerias com nossos clientes para eliminar ameaças à saúde humana. Continuamos fazendo investimentos significativos na nossa rede mundial para atender à demanda crescente dos nossos clientes por recursos de esterilização como uma etapa fundamental dos seus processos de desenvolvimento de produtos.

A alta densidade do cobalto-60 permite que o radioisótopo permaneça ativo em campo por aproximadamente 20 anos. Programas de reciclagem permitem que mais de 99% do material retorne do campo para novas fontes. A baixa pegada de carbono associada ao transporte é amortizada ao longo da vida útil do produto.

A esterilização por irradiação gama tem vantagens ambientais significativas em relação a outras tecnologias de esterilização industrial. O uso de cobalto-60 como fonte de radiação ionizante gera 15 vezes menos consumo de energia elétrica e 12 vezes menos emissões de gases de efeito estufa do que as instalações de raios X, que consomem grandes quantidades de eletricidade, geralmente geradas por tecnologias não renováveis.

Navegar pelas instalações de irradiação gama em todo o mundo

Encontrar locais

Somos líderes no fornecimento mundial de serviços terceirizados de esterilização final e irradiação para os mercados de dispositivos médicos, produtos farmacêuticos, segurança alimentar e aplicações avançadas, além de serviços de consultoria especializada. Nós podemos oferecer suporte a todas as suas necessidades, desde a concepção do produto até a comercialização, para garantir a segurança do seu produto e processo.